Product Design

Participate in customers' full-process parts design and independent design, optimize design solutions, provide a more convenient and faster product design process,and develop new products more efficiently and quickly.

Technological Design

Use professional software to simulate and analyze the sheet metal stamping forming process, improve the reliability of the process plan, shorten the manufacturing process plan cycleand, and improve the development efficiency.

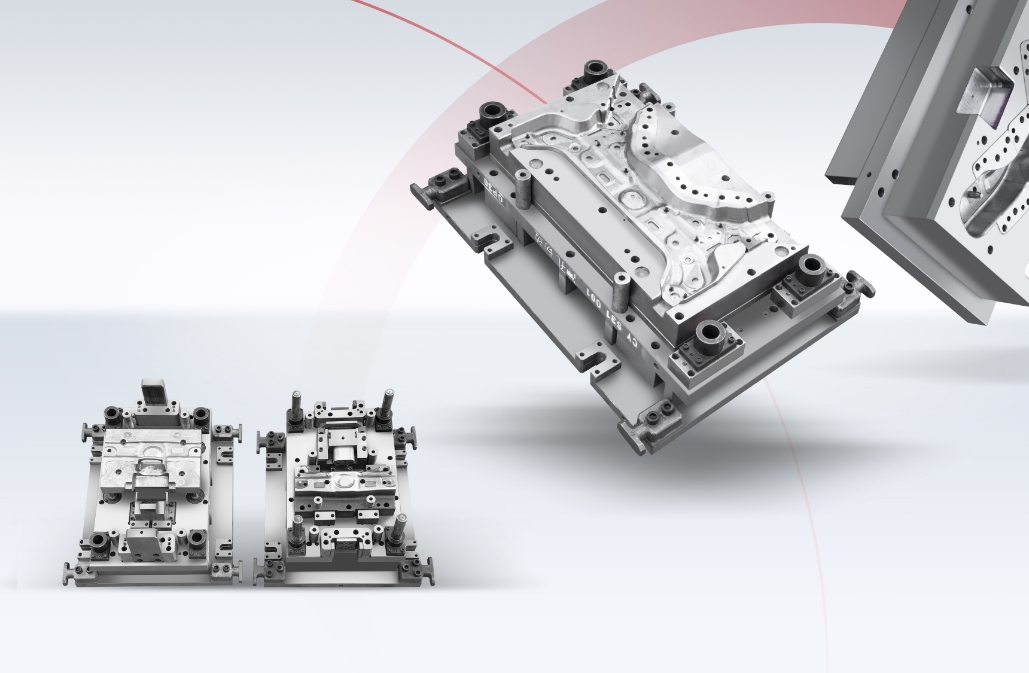

Tooling Design

Focusing on sheet metal stamping mold design for chassis parts, sheet metal welding fixture design. The professional design team provides design solutions more quickly and accurately, then can make a more convenient and low-cost manufacturing solution.

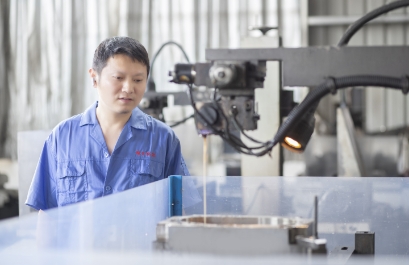

Mold Processing

Our workshop has a variety of high-precision processing equipment. Multi-axis machining center, Medium-fastwire cutting, High precision lathes, Grinding machines, etc., We much rich experience in non-standard processing of sheet metal stamping molds, welding fixtures, inspectiontools, etc.

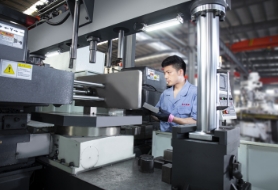

Mold Manufacturing

We have very professional mold manufacturing team, integrating design, processing, assembly, debugging and maintenance. We can complete mold processing and production in the shorte stcycle and provide high-quality and guaranteed precision molds.

Sample Production

2D/3D laser cutting equipment, special stamping and welding production equipment, can quickly and accurately produce prototypes that meet the requirements, effectively shortening the parts development cycle.

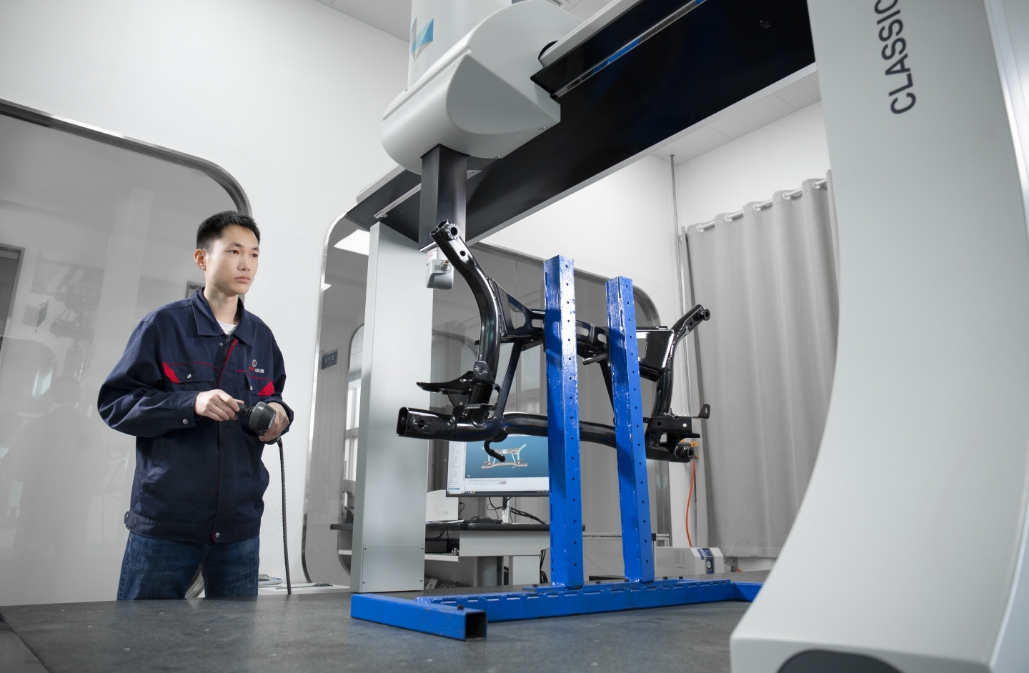

Product Testing

Performance

Three-coordinate measuring equipment can inspect parts in full size, spectrometers and tensile machines can test material properties, and fatigue testing machines can complete product durability tests, providing a fast and accurate basis for sample acceptance testing, and the reliability of productd evelopment is effectively guaranteed.