Manufacturing process

Precise processes create excellent quality

Yearly Manufacturing capacity

Annual Manufacturing Capacity

37000T

Cutting Material Workshop

Machinable

Coil Material

8000T

Machining Workshop

Pipe, Shaft Blank

Workable

24 Million Pieces

Stamping Workshop

Workable

Stamped Single Piece

2 Million Pieces

Welding Workshop

Workable Small Assemblies And Control Arms.

500K Units Each

Welding Workshop

Processable Front/Rear Subframe And Torsion Beam.

3.5 Million Pieces

Painting Workshop

Coatable Products For Painting

3.8 Million Pieces

Assembly Workshop

Assemblable Products

Manufacturng Processes

Manufacturing process

Mold Warehouse

According to different customers and different models, the molds can be found accurately by using board managementat fixed points, positioning, and clear markings.

Can store 8,000 sets of molds.

Flat cutting Plate

The automatic flat cutting machine has the ability to cut 1mm-6mm steel coils, with a monthly cutting capacity reaches to 3,200 tons.

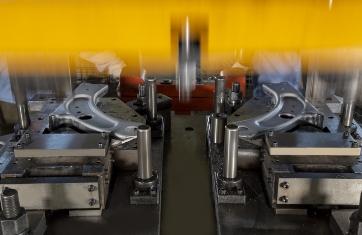

Product Stamping

32T to 1000T stamping machine, totally 78 sets. From large to small parts, including all stamping parts except coverparts, with the production ability of 2 million parts.

And we add a new stamping automation line will further increase stamping production capacity.

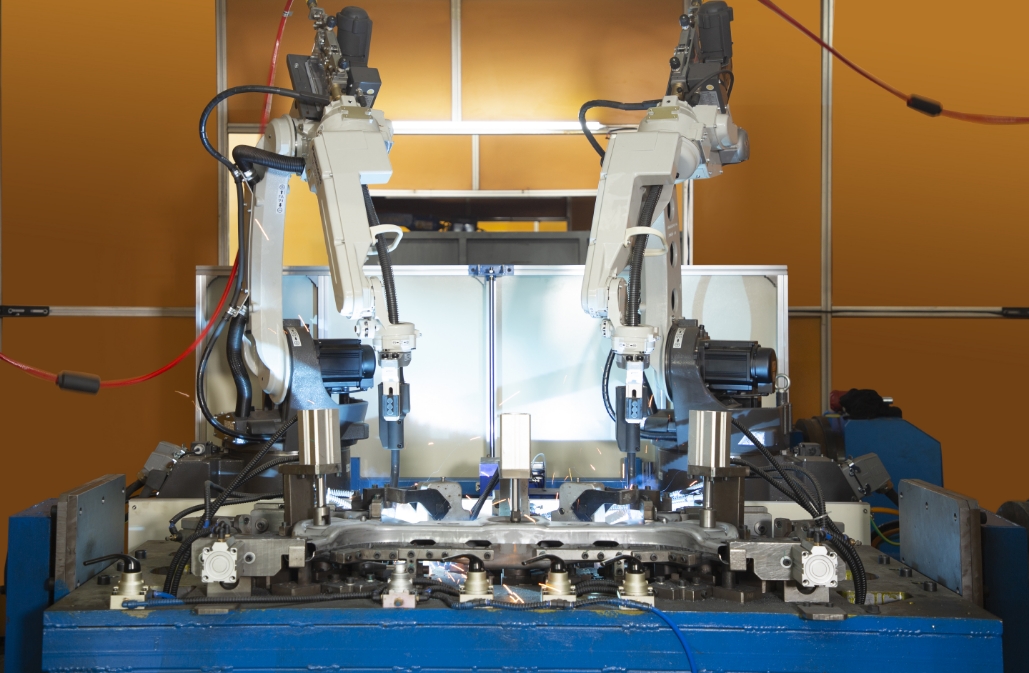

Product Welding

The welding workshop includes:

More than 70 welding robots from Japan's Panasonic and Yaskawa.

9 welding production lines.

It has a monthly output of 250,000 large and small welding assemblies.

Product Painting

Electrophoresis workshop:

The automatic electrophoresis assembly line has the following functions:

Automatically handle surface oil stains, rust, phosphating and other functions;

The salt spray test effect reaches 700H;

The monthly output can reach 320,000 pieces of large and small assemblies.

Painting Inspection

Real-time testing of the electrophoresis assembly line to ensure that various parameter values, corrosion resistance, paint film thickness and other indicators to fully meet the requirements.

Product Assembly

The assembly workshop has a semi-automatic assembly production line. With real-time monitoring and process analysis capabilities for bushing press-in.

lt uses a servo bolt gun to ensure that the torque of each bolt fully meets the requirements.

The monthly output can reach 350K pieces of finished products.

Finished Product Warehouse

Inventory finished products are neatly stacked indesignated areas and locations according to product and customer requirements, and the first-in, first-out operation mode is maintained.